Portable simple mold hardness measurement

Hardness Tester for Self-Hardening Mold /

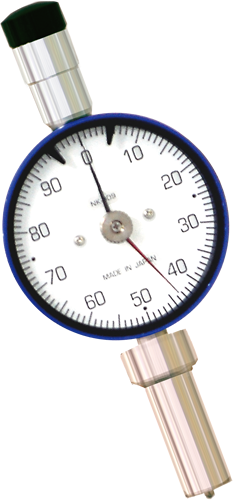

NK-009

- Density of self-hardened mold can be adjusted from the test results.

- Contribution to quality improvement.

- A limiter is provided for setting an allowance range of hardness.

- Peak pointer (red pointer) is provided to indicate the maximum measurement

Feature

Mold hardness measurement after molding

Selection of molding conditions (squeeze pressure and number of jolts).

Batteries

Hardness test method

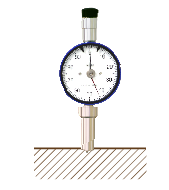

- Use a test mold with a flat test surface accompanied with an opposing surface which is also flat and parallel to the test surface.

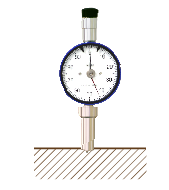

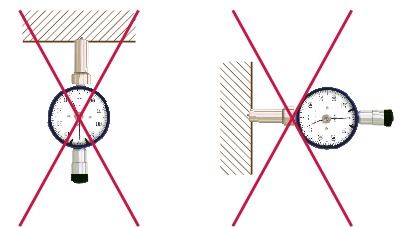

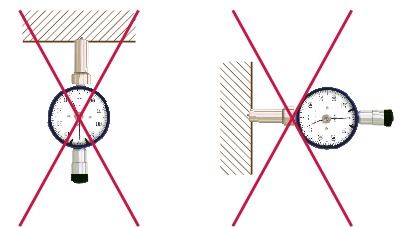

- Hold the tester securely by hand and lower it vertically at a constant speed pressing it on the mold surface. The maximum value is read immediately after the contact. Measurement made askew or upward or on a vertical surface may lead to erroneous results.

| correct |

Incorrect |

|

|

conversion table : Load

| Indicated value |

N |

gf |

kgf |

| 0 |

0.00 |

0 |

0.000 |

| 25 |

11.11 |

1,133 |

1.133 |

| 50 |

22.22 |

2,266 |

2.266 |

| 75 |

33.33 |

3,400 |

3.400 |

| 100 |

44.45 |

4,533 |

4.533 |

* The values are approximate.

Calibration

Calibration at custody (Recommended one a year)

Calibration certificate, Traceability system diagram, inspection report, etc.

Specification [ Type : NK-009 ]

| Target of measurement |

Furan, phenol, CO2, shell mold cores, etc. |

| Type |

Peak pointer type |

Load value

|

0 - 44.450 N ( 0 - 4533 gf ) |

Base shape

|

φ12 mm |

Indentor shape

|

φ2.38 mm |

Measuring direction

|

Downward ( Others directions may cause a malfunction) |

Measuring range

|

0〜100 scale ( 0 - 44.450 N / 0 - 4533 gf ) |

Limiter

|

±5 scale |

| Size |

H123 × W55 × D24 mm |

Weight

|

160 g |

| Storage place |

Dark place |

* Read the usage carefully and use the device properly

Related product

NK-021Hardness Tester for Green Sand Mold

NK-021Hardness Tester for Green Sand Mold  NK-406Compressive Strength Meter for Green Sand Mold

NK-406Compressive Strength Meter for Green Sand Mold