Test Method: TJFS-101 Preparation of standard green sand specimen

1. Application

This applies to preparation method of green sand standard test specimen.

2. Definition

A test specimen prepared by the following method for green sand tests is called the green sand standard specimen.

3. Apparatus

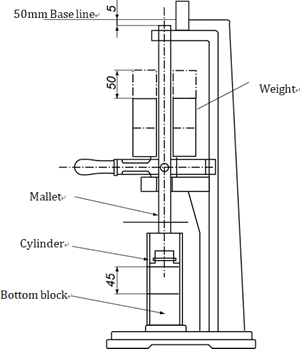

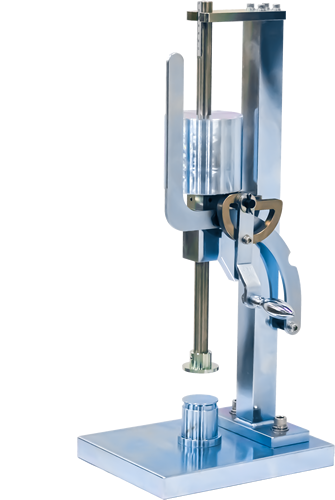

3.1 Sand specimen rammer

The sand specimen rammer as ruled in JIS Z 2601 “Molding sand test method” is used (Fig.1).

Note: The specimen rammer is in principle to be used on a concrete floor. A wooden floor may be used, if the rammer is placed on an iron block shown in Fig.4.

3.2 Specimen preparation cylinder

A cylinder corresponding to JIS Z 2601 “Molding sand test method” with a length of 110 mm to 150 mm is used (Fig.2).

Fig.2 Cylinder for specimen preparation (JIS Z 2601)

Note: The inside surface of the cylinder should be of the roughness 1.6a (6.3s) or less as ruled in JIS B 0601.

3.3 Bottom block for specimen preparation

The bottom block to be inserted in the cylinder should have diameter of 49.5±0.1mm. The material should be iron.

3.4 The push-out block

The push-out block should have outer diameter of 49.1±0.1mm at the face contacting the specimen (Fig.3).

Fig.3 Push out block (JIS Z 2601)

Note: A hole for weight reduction may be machined at the block center.

Fig.4 Base block for specimen rammer (JIS Z 2601)

3.5 Inspection

The dimensional precision should be occasionally checked to assure the precision of the instruments and tools used in this method.

4. Specimen preparation procedure

In preparing a specimen, the cylinder is fitted on the bottom block and sand is poured in the cylinder. Ramming using the rammer is repeated three times so as to make the specimen height to be 50mm±1mm. Then the specimen is pushed out of the cylinder. If the height of the specimen is found to be out of the range of 50±1mm, another specimen must be newly prepared using new sand so as to adjust the height to the required range. The static load by the weight plus mallet is 83.4±1.18N. The ramming is done by free-dropping of the weight of 63.7±0.98N from the height of 50mm±0.5mm. The shrinkage by ramming should be above 5mm.

NKRSand Rammer for Sand Specimen

NKRSand Rammer for Sand Specimen