Test Method: TJFS-103 Green sand permeability test method

P. Application

This applies to green sand permeability test method.

2. Definition:

Permeability is defined as the rate of air flow at a certain pressure through a specimen.

3. Instrument and apparatus

3.1 Permeability tester

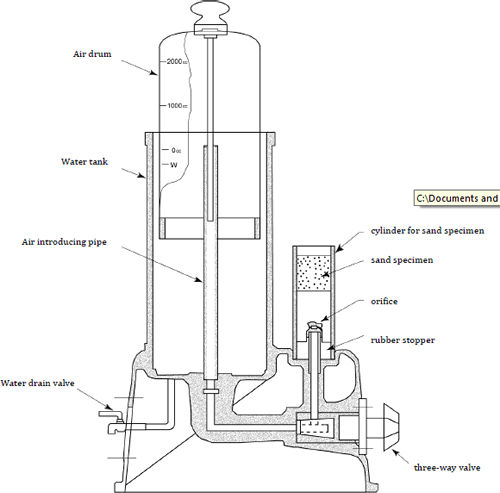

As defined in JIS Z 2601 (Fig.1), the tester is capable of supplying 2000cm3 of air from a drum at a rate of 300cm3/s or higher, while the static pressure of air of volume of 1000cm3 in the drum is maintained at water column height of 10±0.01cm. Air tightness should be such that the drum sinking in 24 hours is 25mm or less.

Fig.1 Permeability tester for green sand (JIS Z 2601)

3.2 Inspection

The instrument and apparatus used in the test are checked at an appropriate interval to maintain the necessary precision.

4. Testing procedure

4.1 Specimen preparation

Test specimens are prepared by the method of TJFS-101 (Preparation of standard green sand specimen), whereas the specimen is not taken out of the cylinder before testing. The sand forming a specimen should not be reused in another test.

4.2 Operation

Air of 2000cm3 is introduced in the drum of the tester by a valve operation, and then the valve is closed. The specimen contained in the cylinder is attached to the air-tight part of the tester. Open the valve and measure the time until 2000cm3 of air is passed through the specimen. The pressure difference between the incoming air and the outgoing air is measured with a water column pressure gauge at the moment when 1000cm3 of air has passed.

4.3 Calculation of permeability

Permeability is calculated by the following equation.

\[P = {V \times H \over p \times A \times T}\]

\[ \left\{ \begin{array}{l} P &= permeability \\ V &= volume \ of \ air \ passed (cm^3) \\ H &= specimen \ height(cm)\\ p &= air \ pressure(cm H_2O) \\ A &= specimen \ cross \ section (cm^2) \\ T &= time \ needed \ for \ passing \ the \ air (min)\end{array} \right. \]

Among the above, V(=2000), H(=5), and A(19.6) are fixed values. If time is measured in terms of second, the following equation is conveniently used.

\[P = {30600 \over p \times T}\]

where

\[ \left\{ \begin{array}{l} t &= time(s) \ needed \ for \ the \ volume \ V \ of \ air \ to \ pass \end{array} \right. \]5. Record

Permeability is expressed in a dimensionless number.

6. Record

The results are calculated to the third decimal place. Tests are repeated three times or more from the same batch of sand and average value is calculated from results within ±5% of the standard deviation.

Reference:

Permeability test may be performed by a simplified method as below. In the simplified method, permeability is obtained by measuring pressure difference when air is passed through a specimen at a constant velocity as determined by an orifice.

1. Orifice

A large orifice and a small orifice are available. The large orifice has a diameter of 1.5mm and when attached to the tester, a volume 2000cm3 air is passed in 0.5±0.01 min. The small orifice has a diameter of 0.5mm and the same volume of air is passed in 4.5±0.09min.

2. Testing procedure

Either the large or the small orifice is attached to the tester. The cylinder containing a specimen is attached to the tester. The valve is opened to pass air from the drum. Pressure difference is measured at the moment when air in the drum is 1000cm3. Permeability is determined from the Table1. The small orifice is used when permeability is 40 or less. The large orifice is used when permeability is 40 or higher. A tester in which air pressure and air volume are measured by electrical means or others may be used in place of the tester described above.

3. Record

When the simplified method is used, it must be specified so in the report.

Relationship between air pressure and air permeability (Quick method)

| Pressure cmH2O (mbar) |

permeability | Pressure cmH2O(mbar) |

permeability | ||

|---|---|---|---|---|---|

| small orifice 0.5mm |

large orifice 1.5mm |

small orifice 0.5mm |

large orifice 1.5mm |

||

| 0.1(0.098) | | | | | 5.1(5.00) | 15.0 | 136 |

| 0.2(0.20) | | | | | 5.2(5.10) | 14.5 | 132 |

| 0.3(0.29) | | | | | 5.3(5.20) | 14.1 | 128 |

| 0.4(0.39) | | | 2485 | 5.4(5.30) | 13.7 | 124 |

| 0.5(0.49) | | | 1978 | 5.5(5.39) | 13.3 | 120 |

| 0.6(0.59) | | | 1638 | 5.6(5.49) | 12.9 | 117 |

| 0.7(0.69) | | | 1399 | 5.7(5.59) | 12.5 | 114 |

| 0.8(0.78) | | | 1214 | 5.8(5.69) | 12.2 | 110 |

| 0.9(0.88) | | | 1073 | 5.9(5.79) | 11.8 | 107 |

| 1.0(0.981) | | | 960 | 6.0(5.88) | 11.4 | 104 |

| 1.1(1.08) | | | 867 | 6.1(5.98) | 11.1 | 101 |

| 1.2(1.18) | | | 790 | 6.2(6.08) | 10.8 | 98 |

| 1.3(1.27) | | | 725 | 6.3(6.18) | 10.5 | 95 |

| 1.4(1.37) | | | 668 | 6.4(6.28) | 10.2 | 92 |

| 1.5(1.47) | | | 620 | 6.5(6.37) | 9.9 | 89 |

| 1.6(1.57) | | | 578 | 6.6(6.47) | 9.5 | 86 |

| 1.7(1.67) | | | 540 | 6.7(6.57) | 9.3 | 84 |

| 1.8(1.77) | | | 507 | 6.8(6.67) | 9.0 | 81 |

| 1.9(1.86) | | | 477 | 6.9(6.77) | 8.7 | 79 |

| 2.0(1.96) | 49.7 | 450 | 7.0(6.86) | 8.4 | 76 |

| 2.1(2.06) | 47.0 | 426 | 7.1(6.96) | 8.2 | 73 |

| 2.2(2.16) | 44.6 | 403 | 7.2(7.06) | 7.9 | 71 |

| 2.3(2.26) | 42.3 | 383 | 7.3(7.16) | 7.6 | 69 |

| 2.4(2.35) | 40.3 | 365 | 7.4(7.26) | 7.4 | 66 |

| 2.5(2.45) | 38.4 | 348 | 7.5(7.36) | 7.1 | 64 |

| 2.6(2.55) | 36.6 | 332 | 7.6(7.45) | 6.9 | 62 |

| 2.7(2.65) | 35.0 | 317 | 7.7(7.55) | 6.6 | 59 |

| 2.8(2.75) | 33.5 | 304 | 7.8(7.65) | 6.4 | 57 |

| 2.9(2.84) | 32.1 | 291 | 7.9(7.75) | 6.1 | 55 |

| 3.0(2.94) | 30.8 | 279 | 8.0(7.85) | 5.9 | 53 |

| 3.1(3.04) | 29.6 | 268 | 8.1(7.94) | 5.7 | 51 |

| 3.2(3.14) | 28.4 | 258 | 8.2(8.04) | 5.4 | 49 |

| 3.3(3.24) | 27.3 | 248 | 8.3(8.14) | 5.2 | 46 |

| 3.4(3.33) | 26.4 | 239 | 8.4(8.24) | 5.0 | 44 |

| 3.5(3.43) | 25.4 | 230 | 8.5(8.34) | 4.7 | 42 |

| 3.6(3.53) | 24.5 | 222 | 8.6(8.43) | 4.5 | 40 |

| 3.7(3.63) | 23.6 | 214 | 8.7(8.53) | 4.3 | 38 |

| 3.8(3.73) | 22.8 | 207 | 8.8(8.63) | 4.0 | 36 |

| 3.9(3.82) | 22.0 | 200 | 8.9(8.73) | 3.8 | 33 |

| 4.0(3.92) | 21.3 | 193 | 9.0(8.83) | 3.6 | 31 |

| 4.1(4.02) | 20.6 | 187 | 9.1(8.92) | 3.3 | | |

| 4.2(4.12) | 19.9 | 180 | 9.2(9.02) | 3.1 | | |

| 4.3(4.22) | 19.2 | 175 | 9.3(9.12) | 2.6 | | |

| 4.4(4.31) | 18.7 | 169 | 9.4(9.22) | 2.6 | | |

| 4.5(4.41) | 18.1 | 164 | 9.5(9.32) | 2.3 | | |

| 4.6(4.51) | 17.5 | 159 | 9.6(9.41) | | | | |

| 4.7(4.71) | 16.9 | 154 | 9.7(9.51) | | | | |

| 4.8(4.71) | 16.4 | 149 | 9.8(9.61) | | | | |

| 4.9(4.81) | 15.9 | 144 | 9.9(9.71) | | | | |

| 5.0(4.90) | 15.5 | 140 | 10.0(9.807) | | | | |

NKP-V2Permeability Tester

NKP-V2Permeability Tester