| 1. |

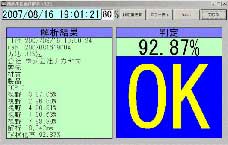

Follows JIS standard. |

| 2. |

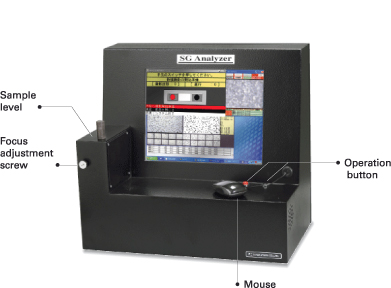

Neither mouse nor keyboard is needed for usual measurement, as two buttons system is applied. |

| 3. |

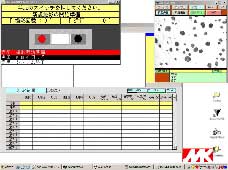

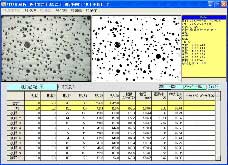

Quick work operation is expected, as taken graphite image is automatically analyzed. |

| 4. |

No personal error by operators is existed in the measured result, as setting of factors needed for analyze have been done in advance of operation. |

| 5. |

Printout of the result is automatically done after analysis, if a printer has been connected. |

| 6. |

It is need only simple work with two buttons, that operation is very easy. (Though in the case of lot control, it needs keyboard input.) |

| 7. |

For operation process control, it is applicable to set on working floor. |

| 8. |

It is booted on Windows and extraction of data is applicable using USB port.(It is easy to confirm data, as they are saved in a date file.) |