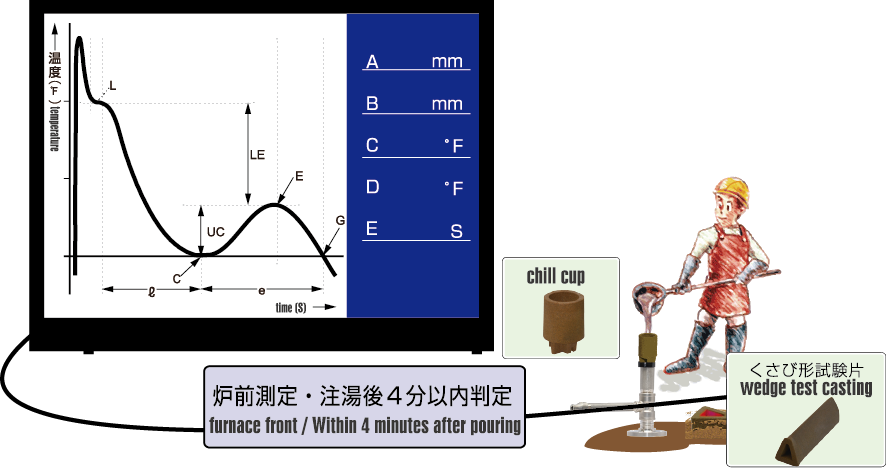

A chill depth determining instrument by thermal analysis

Chill Depth Meter

Chill depth determination within four minutes after pouring an inoculated melt in a chill test cup

*The conventional wedge test should be used in parallel until a sufficient reproducibility is confirmed.

- furnace front

- Within 4 minutes after pouring

Feature

The chill tester automatically makes evaluation of chilling tendency, based on the data as indicated in A) to D) together with the wedge test results. The specific conditions of the raw materials, melting method, and melt treatment are taken into consideration.

Contents

- A) wedge test result (mm)

- B) chill depth (mm)

- C) LE (°F)

- D) undercooling (°F)

- E) judgment of inoculation effect (s)

depending on the cooling curve and the phase diagram. See 1, 2 , 3 below.

The close relationship between the chilling tendency and the thermal analysis (cooling curve).

- The degree of undercooling

- Temperature range LE between the primary point L and the eutectic point E.

- The ratio of time

from the primry point L and the undercooling point C over the time e bewteen the undercooling and the end of eutectic.

from the primry point L and the undercooling point C over the time e bewteen the undercooling and the end of eutectic.

Steps before the real application

i) Pour the inoculated melt into the chill cup and the wedge test mold, provided free of charge.

ii) The chill cup data is automatically recorded.

iii) Measure the chill width of the wedge test casting and input the value to the tester.

iv) Correlation is automatically obtained between the chill test and chill cup results from 20 to 30 tests.

v) Correction factor is determined based on comparison. Then do some running tests.

vi) Real application is started.

Specification

- Data is transferred through USB.

- Data can be stored and reviewed later.

- Touch Panel

- Windows PC