Test Method: TJFS-204 Green sand total clay test method

P. Application

This applies to the test method of green sand total clay content determination.

2. Definition

The total clay content of green sand includes not only the clay as a mineral, but also grains that fall in water at 21 to 26 degree C at velocity of 25mm per minute or slower (grain diameter of such substance is usually 20μm or smaller), and water soluble substance.

3. Instrument and apparatus

3.1 Balance

A balance of the precision of 0.01g is used.

3.2 Rotary washer

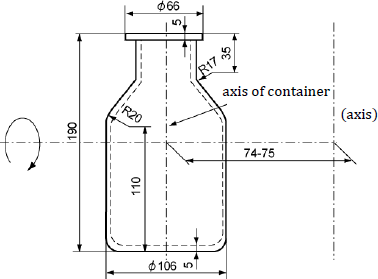

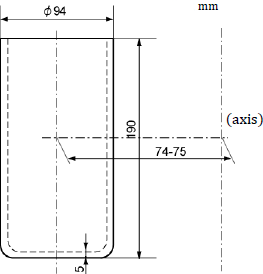

A container of Fig.1 or Fig.2 is used. A washer that give the container axial rotation of 62 to 72 rotations per minute with a rotation radius of 74 to 75mm is used.

Fig.1 Container(1) for rotary washer

Fig.2 Container(2) for rotary washer

3.3 Supersonic disperser

A supersonic disperser of frequency of 25 to 30kHz and output power of 150 to 200W is used.

3.4 Clay separator

Either of the following two is used.

Fig.3 Separation of clay by a siphon

- A siphon of an internal diameter of 5 to 6mm is combined with a container as in Fig.3. As the container, either the ones in Fig.1 or 2 or a beaker of 2000ml capacity is used.

- A water-flow washer of the shape and size of Fig.4 is used. Note: When a metallic one is used, corrosion resistance is required.

Fig.4 Water-flow washer

4. Sample

Green sand is dried at 105±5 degree C until the weight reaches a constant, and is then cooled in a desiccator to be used as a sample.

Note: Normally about 100g sand is necessary for a test and drying time to a constant weight is 1 to 2 hours.

5. Testing procedure

5.1 Dispersion of clay into water

Clay is dispersed into water by either of the following methods.

- Rotary washer A sample of 50g is put in a container to which 475ml water and 25ml of 3% sodium hydroxide are added. The container is set in a rotary washer and given stirring by rotation for 1 hour. After rotation, water is poured in the container to wash down any sand on the wall and to form a depth of about 15cm in the container.

- Boiling Sample of 50g is put in an evaporating container of about 400ml in capacity and 300ml water and 2.5ml of 3% sodium hydroxide solution, or 20ml of 1.5% sodium pyrophosphate. The mixture is boiled for 30 minutes. During boiling, the volume of the mixture in the container is kept above 105 ml by adding water whenever necessary. Explosive boiling should be avoided. After boiling, the mixture is poured in a beaker to form a depth of about 15cm.

- Supersonic disperser Sample of 50g is mixed with 300ml water and 2.5ml of 3% sodium hydroxide solution, or 20ml of 1.5% sodium pyrophosphate. The mixture is treated with a supersonic disperser for 10 to 15 minutes and then poured in a beaker to form a depth of about 15 cm.

5.2 Clay removal

Clay is removed by either of the following methods.

- Siphon The mixture after the operation of item 5.1 is mixed well and left still for 10 minutes. The water in the upper part of the container is discharged by a siphon until the depth becomes 25mm from the bottom. Water is added to the depth of about 15cm, mixed well, kept for 10 minutes, and the upper layer is discharged by the siphon to the depth of 25mm. On the third repetition and later, water is added also to the depth of 15cm, but kept for only 5minutes before discharging. The same is repeated until the water becomes clear. The residual sand grains are dried at 105±5 degree C until the weight becomes constant. It is weighed at room temperature after cooled in a desiccator.

- Use of water-flow washer The mixture after the operation of item 5.1 is fully moved into a water-flow washer. Water flow of about 260ml per minute is given from the bottom to wash out clay. The flow is continued until the discharged water becomes clear. The residual sand grains are dried at 105±5 degree C until the weight becomes constant. It is weighed at room temperature after cooled in a desiccator.

5.3 Calculating the total clay content

The total clay content is calculated by the following equation.

\[TC = { ( W_1 - W_2 ) \over W_1 } \times 100 \]

where

\[ \left\{ \begin{array}{l} TC &= green \ sand \ total \ clay \ content \\ W1 &= weight \ of \ the \ initial \ sample \ (g) \\ W2 &= weight \ of \ the \ residual \ sand \ (g) \end{array} \right. \]Note: Although the sample weight is designated to be 50g, a slight deviation is permissible.

6. Expression

The total clay content is expressed in %.

7. Record

The result is calculated to the first decimal place. Test is repeated two times or more and averaged using values within 5% deviation.

NKW

NKW