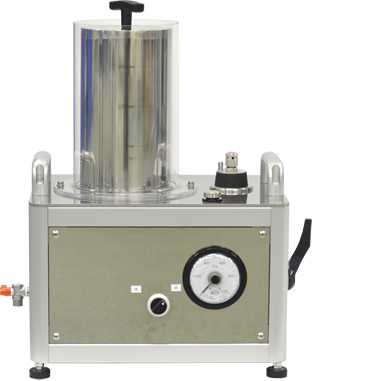

Permeability Tester (Analog type) NKP-V2

- TJFS-103 Green sand permeability test method Standard compliant product

Overview

This apparatus is for quick and precise measurement of permeability of green sand mold, dry sand mold, and other sand molds following the standard set by the molding sand research committee of Japan Foundrymen's Society (NIK).

An air supply tube stands vertically upwards at the center of a water tank bottom. The top of the tube is above the water level in the tank. Air is supplied through a three way valve and the tube to an air chamber, which has a vertical tube from the top which slides inside the air supply tube. The outside of the air chamber is marked with lines designated as "W" at the lowest position, and "0", "1000", and "2000" at higher positions, where "W" corresponds to the standard water level, and other figures correspond to the volume of air discharge at the respective height of the air chamber. In other words, the air volume between the "0" line and "2000" line is 2000 cc. The three way valve is installed in a casing and manipulated by a manually moved handle. Three positions of the valve are indicated; "Close" is for stopping the air flow, "Measure" is for discharging air for measurement, and "Open" is for introducing air to push up the air chamber. A rubber stopper is attached above the three way valve, and an orifice is attached at its top. A cylinder containing the test sand can be screwed above the stopper. A water column is attached on the front side and connected to the test sand cylinder for measuring air pressure.

How to use the tester

Quick method

The apparatus is placed on a horizontal desk. The three-way valve is turned to "Open" to introduce water so that the air chamber is floated to the mark "W". Then the valve is turned to "Measure" to introduce air so that the air chamber is lowered to a position slightly below the "0" line, and then the valve is turned to "Close" to stop air flow. An orifice, either the small one or the large one, depending on the sand grain fineness, is screwed in the rubber stopper after inserting a rubber ring for preventing air leak. The test sand is rammed using a sand rammer into a test piece cylinder of a standard shape, and the cylinder with the sand is tightly pushed in the rubber stopper. The valve is turned to "Measure" to raise air pressure in the sand cylinder. After reading the value of the pressure gauge, the valve is turned to "Close". Table.1 gives the permeability value corresponding to the pressure value thus measured.

Standard method

\[Permeability = {V \times H \over P \times A\times T}\]

- V =air volume passed through the test piece (cc) 2000cc

- P = pressure difference between the upper side and lower side of the specimen (Pa) (P = Pa ÷ 98)

- A = sectional area of the specimen (A = 19.635cm2)

- H = height of the specimen (cm) (5.0 ± 0.1cm)

- T = time necessary for the air of 2000cc to pass the specimen (min)

Testing of dry sand mold

A standard specimen (50mm in diameter and 50mm in height) is prepared with a sand rammer and is taken out with a push rod for drying. A weak specimen is taken out on a disc of 50mm diameter and sent to drying on the disc.

The specimen is dried at 105 to 115 degree C for one to two hours and taken out for cooling. After cooling, it is inserted in a dry sand permeability specimen cylinder. The valve on the cylinder is opened and air is sent from the rubber bulb to the rubber sheath in the cylinder for ensuring pressure tight support of the specimen. The cylinder is inserted into the rubber stopper, and permeability is measured in the same way as the case of the green sand.

Calibration of orifice

The air chamber should be lifted very slowly not to disturb water in the tank.

Orifice should be kept clean. The holes should not be deformed, and hence, they must be checked occasionally. Size of the holes can be checked in the following manner. Attach an orifice to the apparatus and let the air in the air chamber flow out

through the orifice without attaching a test piece cylinder. Time is measured while the air chamber sinks from the level of "0" to "2000". If the time value does not fit the standard shown below, the hole size of the orifice must be corrected.

| Air pressure in chamber Time necessary for discharging air of 2000cc |

= | Large orifice: 30s Small orifice: 4m30s (allowance: 2%) |

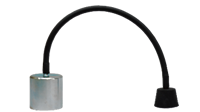

Permeability test of mold surface

An attachment is provided for measuring permeability of a manufactured mold or core. One end of the rubber tube is inserted to the rubber stopper of the permeability tester, and the rubber receptacle at the other end is pressed against the mold surface to be measured. Then the test is performed in the same manner as in the case of test pieces.

Though the precision of this method is not as high as the other tests, it is a convenient way of knowing the approximate permeability of mold or core as manufactured.

Calibration

The relation between air pressure and permeability

- Use the small orifice for medium to fine sand grains.

- Use the large orifice for medium to coarse sand grains.

| pressure (Pa) |

0.5mm small orifice |

1.5mm large orifice |

pressure (Pa) |

0.5mm small orifice |

1.5mm large orifice |

pressure (Pa) |

0.5mm small orifice |

1.5mm large orifice |

pressure (Pa) |

0.5mm small orifice |

1.5mm large orifice |

|||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 10 | - | - | 260 | 35.8 | 325 | 510 | 14.5 | 132 | 760 | 6.5 | 58 | |||

| 20 | - | - | 270 | 34.2 | 310 | 520 | 14.1 | 128 | 770 | 6.2 |

56 | |||

| 30 | - | - | 280 | 32.6 | 296 | 530 | 13.7 | 124 | 780 | 6.0 | 54 | |||

| 40 | - | 2434 | 290 | 31.3 | 283 | 540 | 13.3 | 120 | 790 | 5.8 | 52 | |||

| 50 | - | 1944 | 300 | 30.1 | 272 | 550 | 12.9 | 117 | 800 | 5.5 | 50 | |||

| 60 | - | 1614 | 310 | 28.9 | 262 | 560 | 12.5 | 114 | 810 | 5.3 | 47 | |||

| 70 | - | 1378 | 320 | 27.6 | 251 | 570 | 12.1 | 109 | 820 | 5.1 | 45 | |||

| 80 | - | 1186 | 330 | 26.7 | 242 | 580 | 11.7 | 106 | 830 | 4.8 | 43 | |||

| 90 | - | 1050 | 340 | 25.7 | 232 | 590 | 11.3 | 103 | 840 | 4.6 | 41 | |||

| 100 | - | 941 | 350 | 24.8 | 224 | 600 | 11.0 | 100 | 850 | 4.4 | 39 | |||

| 110 | - | 852 | 360 | 23.9 | 216 | 610 | 10.7 | 97 | 860 | 4.0 |

37 | |||

| 120 | - | 776 | 370 | 23.0 | 208 | 620 | 10.4 | 94 | 870 | 3.8 |

33 | |||

| 130 | - | 708 | 380 | 22.1 | 201 | 630 | 10.1 | 91 | 880 | 3.7 | 31 | |||

| 140 | - | 654 | 390 | 21.4 | 194 | 640 | 9.8 | 88 | 890 | 3.3 | - | |||

| 150 | - | 607 | 400 | 20.7 | 188 | 650 | 9.4 | 85 | 900 | 3.2 | - | |||

| 160 | - | 567 | 410 | 20.1 | 181 | 660 | 9.2 | 83 | 910 | 2.6 | - | |||

| 170 | - | 529 | 420 | 19.3 | 176 | 670 | 8.9 | 80 | 920 | 2.6 | - | |||

| 180 | - | 495 | 430 | 18.8 | 170 | 680 | 8.6 | 78 | 930 | 2.3 | - | |||

| 190 | - | 466 | 440 | 18.2 | 165 | 690 | 8.3 | 75 | 940 | - | - | |||

| 200 | 48.6 | 440 | 450 | 17.6 | 160 | 700 | 8.1 | 72 | 950 | - | - | |||

| 210 | 46.0 | 417 | 460 | 17.0 | 155 | 710 | 7.8 | 70 | 960 | - | - | |||

| 220 | 43.6 | 394 | 470 | 16.4 | 149 | 720 | 7.5 | 68 | 970 | - | - | |||

| 230 | 41.3 | 374 | 480 | 15.9 | 144 | 730 | 7.3 |

65 | 980 | - | - | |||

| 240 | 39.4 | 357 | 490 | 15.5 | 140 | 740 | 7.0 | 63 | 990 | - | - | |||

| 250 | 37.5 | 340 | 500 | 15.0 | 136 | 750 | 6.8 |

61 | 1000 | - | - |

Specification [ Type : NKP-V2 ]

| dimension | W500 × H500 × D320 mm |

|---|---|

| weight | About18kg |

Sold separately

|

|

| Pump / Sand cylinder | Tool |

NKP-V3Digital Permeability Tester

NKP-V3Digital Permeability Tester