Universal Molding Sand Strength TesterNKU

- TJFS-204 Green sand total clay test methodStandard compliant product

How to test green mold, baked mold, and core

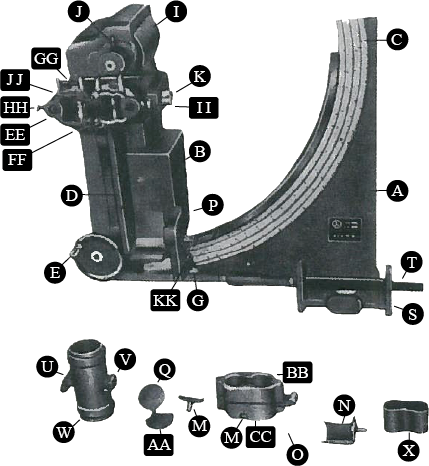

Fix the tester on a flat concrete block or a sturdy wood block. The swing weight (B) is adjusted to the horizontal position using a level gauge and a pair of adjusting screws on the bed plate (A). The horizontal position can be easily found by matching the zero line of the aluminum press arm (KK) that is attached at the end of the swing arm (B) and the zero line of the measure grade (C). Then the moving indicator (G) is attached to the press arm (KK), while rotating the handle (E) counter-clock-wise to place the press arm (D) at the end position. The moving indicator (G) is a magnetic iron piece which is left staying at the position corresponding to the moment of breakage of a sand test piece.

How to use

1.Compression strength test of green sand mold

The convex parts of the two press piece (AA) and (M) are inserted in the concavity (P) so that the two ratchets of the both press pieces match at the same height. For ease of operation, it is recommended to place on the left side the one of the two press pieces that has a free moving top, namely on the side of the press arm. A test piece properly made by using a sand rammer is inserted between the two press piece (AA) and (M) and fixed with the four ratchets. After setting the moving indicator (G), rotate the handle (E) clock-wise to push up the press arm (D). In other words, the test piece pushes up the swing weight (B).

The load of the swing weight on the test piece increases in proportion to the rotation of the handle (E), and it breaks at the moment when it can no more bear the weight (B). The swing weight (B) and press arm (KK) return to the original position, leaving the magnetic moving indicator at the position of the maximum load. The strength (kg/cm2) is read from the position of the moving indicator on the measure grade “GREEN COMP”.

2.Shear strength of green sand mold

(N) and (O) are used for this test. (N) is inserted in the concavity (P) on the side of the press arm and (O) is inserted in the other side. Their position is fixed by knocking.

This set of parts shears off the test piece by pressing at its middle point with its stepped part.

Setting of the test piece and rotation of the handle are done in the same manner as in the case of compression test. Strength (kg/cm2) is read from the position of the moving indicator on the measure grade “GREEN SHEAR” at the bottom.

3.Compression strength test of baked sand mold

A space for test piece insertion is provided by removing the bolts (JJ), ((K), parts for arms, and tensile test attachments (EE) and (FF).

Press pieces (AA) and (M) are inserted in a concave provided by removing bolts (JJ) and (K) in the same manner as in the case of green sand mold. Strength is read from the position of the moving indicator on the measure grade “DRY COMP”

Note

- For sand sample of about 100 g, drying time may be 1 to 2 hours.

- Clay content as determined by this method is a total of the pure clay content plus some other materials possibly separated in the process.

Sand content is defined as the difference between 100 and the clay content as determined by this method. - Binders of molding sand may contain clay as well as other inorganic and organic materials. This method is applied to sands having clay as binder.

- Because of the variable continuous transmission, the rotational speed can be controlled between 600 to 3000 RPM in order to attain desired degree of stirring or time for stirring. The standard value is 50 to 1500 RPM or 60 to 1800 RPM.

- In case distilled water is not available, it may be replaced with ordinary water.

- It is recommended to make two or more tests on the same sand, and take an average from data with a standard deviation within ±5%.

Specification (This product is not for sale)

| Type | NKU |

|---|---|

| dimension | 557 × 514 × 315 mm |

Capacity

| green mold compression strength | 1.32 kg/cm2 |

|---|---|

| baked mold compression strength | 6.60 kg/cm2 |

| green mold shear strength | 1.04 kg/cm2 |

| baked mold shear strength | 5.20 kg/cm2 |

| core ensile strength | 20.80 kg/cm2 |

| core binder | 20.80 kg/cm2 |

NK-406Compressive Strength Meter for Green Sand Mold

NK-406Compressive Strength Meter for Green Sand Mold